truckwings

How It Works

- Deploys Automatically

- Reduces Emissions

- Improves Stability & Driver Comfort

- Fuel Savings of 3-6%

Design

Fully Automated

The TruckWings patented design uses vehicle speed and smart sensors to automatically deploy. Aerodynamic panels unfold and retract with no need for driver input.

Improved Performance

TruckWings reduces the energy lost in the tractor-trailer gap, lowering wind drag, improving fuel economy and reducing carbon emissions. Most fleets see 3-6% improvement in fuel efficiency. Each TruckWings device reduces 20,000 lbs/yr in carbon emissions. Analysis and customer reviews confirm an improvement in vehicle stability at higher crosswinds by reducing the side forces acting on the trailer. This leads to improved safety and vehicle control.

Aerodynamic Concept

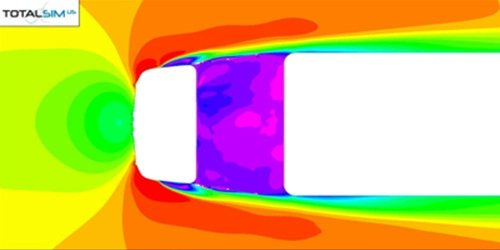

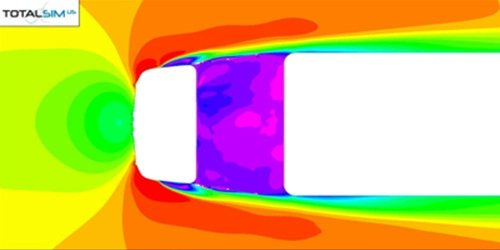

The device works by reducing the energy lost in the tractor-trailer gap. This is achieved by eliminating the gap’s cross-flow seen at higher crosswind angles and by controlling the flow around the cab and onto the trailer – reducing the wake off the cab. The energy gain is realized as a rise in static pressure within the gap that acts to push on rearward facing surfaces of the cab, reducing its drag.

Operation

Real-Time Deployment

TruckWings are controlled by TruckLabs Telematics, an in-cab device tapped into the tractor’s CAN bus to determine vehicle speed and other conditions. Once highway speeds above 52mph are reached, TruckWings automatically deploy and retract when speed goes below 50mph.

Smart-Sensing Technology

A distance sensor mounted to each TruckWings frame ensures adequate clearance to the trailer is present before deploying. Cloud-connected telematics on each device allow for transparent, uptime reporting through customer dashboards.

Driver-Free Convenience

No manual driver interaction is required. When truck speed and trailer distance conditions are met for deployment, a signal is sent to pressurize air cylinders to deploy the TruckWings. TruckWings automatically retract when no trailer is detected or detected at a distance too close to the tractor. The aerodynamic device retracts at speeds below 50mph, allowing for in-city maneuverability.

Take It From the Experts

TotalSIM US, an independent leader in assessing aerodynamic devices, verified the savings claims of TruckWings using Computational Fluid Dynamics (CFD).

Reliability

Designed to Last

TruckWings are designed to last the life of your tractor while only requiring minimal maintenance on easily serviceable components on the back of the cab. On average, fleets spend $30 per 100k miles towards TruckWings maintenance and repairs.

Durable and Low Maintenance

Proven durability through 400+ million miles of testing. Unlike side extenders, TruckWings receive little damage because they are able to fold away while driving under 52mph.

Ease of Use

Fits with fleets PMI schedule. Components designed for easy removal and replacement when needed.

Connectivity

Connected Aerodynamics

TruckWings is the world’s first connected aerodynamics device for the Class 8 market. Real-time telematics track deployment with every mile to help fleets recognize their true return on investment with TruckWings.

Real-Time Visibility

Performance metrics and system health visible to fleet operators across their TruckWings fleet.

Continuous Software Updates

Over-the-air software updates introduce new features, functionality and performance.

Road Ready Today

Available today for most major OEM tractor models and fuel types for both pre-delivery and retrofit applications.

Fast and Easy to Install

- Total install takes less than 2 hours

- Universal design fits most tractors

- Onsite installation and training to multiple installation location options

Trusted by