Facing Challenges Meeting Sustainability Goals? Look at Your Fleets’ Aerodynamics

How to Harness Aerodynamics to Reduce Drag, Improve Fuel Efficiency for Fleets

Automation, Targeted Design Boost Performance by Closing the Gap

Improving fleet performance, reducing emissions and reducing fuel costs are top priorities for the trucking industry, especially as fuel costs soar and green policy pressures increase. Fleet operators searching for innovations and solutions have eyed better aerodynamics as an easy answer.

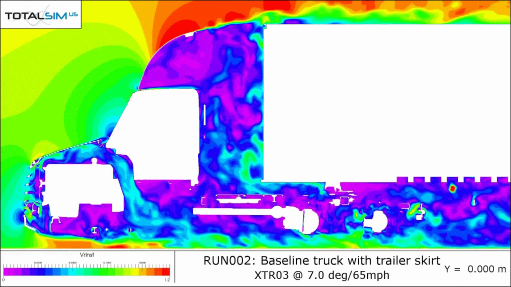

The pocket of air between the tractor and trailer – or gap – is the most common cause for drag, which costs money and wastes fuel. How to close the gap while a truck is at highway speeds, yet maintain maneuverability on surface streets has posed a challenge for operators.

Extra long, static cab extenders have provided some relief. But, while they help close the gap and reduce drag, they interfere with trailer clearance for tight turns, making them a potential nightmare for in-town driving conditions.

Automated design has uncovered a better way to close the gap. Closing the gap reduces buffeting and trailer sway in cross-winds outperforming even the longest side-extenders on the market today.

Automation in Aerodynamics Delivers New Option

Introduced by TruckLabs in 2015, TruckWings is a tractor-mounted device that has unlocked a new frontier in Class 8 efficiency through the use of active aerodynamics. Developed by hardware engineers, software developers, and data scientists to systematically manage the gap in all conditions, TruckWings is innovating the industry.

Closing the gap reduces buffeting and trailer sway in cross-winds outperforming even the longest side-extenders on the market today.

The TruckWings device requires zero driver input to deploy or retract, delivering an automated solution that keeps people and property safe, while achieving the savings and sustainability improvements fleet owners are seeking.

How Do TruckWings Work?

TruckWings is the only fully automated solution that works without driver interaction.

As a smart device, TruckWings receives real-time information about the speed of a tractor-trailer to determine when to open and close. When the vehicle reaches 52 mph, a signal is sent from the cab to automatically deploy the TruckWings. When speed dips to 50 mph or below, TruckWings automatically retract before the truck needs to make sharp turns.

The standalone TruckWings controller is installed on the truck’s CAN J1939 data link. Additionally, a sensor scans the area behind the TruckWings to ensure adequate clearance to the trailer exists.

Five of the 10 largest fleets in North America have installed TruckWings on their trucks, logging over 400 million miles. Each one makes the savings and sustainability impact of taking two vehicles off the road every year.

TruckWings reduces the energy lost in the tractor-trailer gap, lowering wind drag, improving fuel economy and reducing carbon emissions. Most fleets see 3-6% improvement in fuel efficiency. Each TruckWings device reduces 20,000 lbs/yr in carbon emissions. Analysis and customer reviews also confirm an improvement in vehicle stability at higher crosswinds by reducing the side forces acting on the trailer. This leads to improved safety and vehicle control.

As more fleet operators turn to solutions that drive down fuel costs and improve emissions rates, TruckWings automation is delivering a powerful boost to fuel efficiency and sustainability efforts.